CURRENT PROJECTS

Salt Lake One Powered Ankle Prosthesis

Salt Lake One is a fully powered robotic foot and ankle prosthesis. An update to our first powered ankle, Clyde, Salt Lake One incorporates an updated ballscrew actuation system, a frameless electric motor, and a large spring to biomimetically store energy during rollover and release it during push. In combination with novel kinematics, these components enable high-power (200+ Nm of torque, higher than biological walking) and high range-of-motion (+30°/-25°) in a low-profile, low-weight form factor. These characteristics make Salt Lake One one of the most highly functional powered foot and ankle prostheses in the world. Publication pending.

Semi-Active Ankle Prosthesis

The semi-active ankle combines a novel disc brake mechanism with a series elastic actuator to create a brakeable series elastic actuator (BSEA), enabling two modes of operation: Passive and Active. In Passive mode, the BSEA functions as a purely passive spring by locking the actuator to achieve device functionality akin to a passive prosthesis. This mode allows the user to perform activities requiring high torque, such as level ground walking, ramp ascent, and ramp descent. In Active mode, the BSEA functions like a conventional series elastic actuator, achieving ankle articulation and positive/negative power generation similar to powered prostheses. Active mode allows the user to perform activities such as sit-to-stand transitions, stair ascent, and stair descent. Dynamic control of the brake between and within activity transitions allows the semi-active ankle prosthesis to switch between Passive and Active modes, yielding additional advantages over traditional passive and powered prostheses. This includes minimizing energy consumption between and within gait activities and achieving slope adaptation behavior by modulating the equilibrium position of the Passive mode.

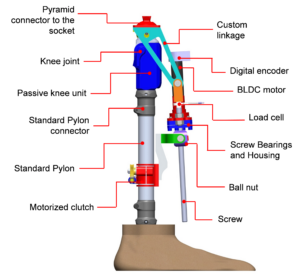

Direct Ball Screw Drive Knee Prosthesis

The Direct Ball Screw Drive Knee Prosthesis combines a quasi-direct drive with a variable transmission in a novel torque-sensitive actuator. The actuator passively adapts the transmission ratio in response to changes in knee torque, significantly increasing the actuator’s torque/speed capabilities. This combination of technologies results in an actuator that is powerful, lightweight, quiet, and matches the impedance of a biological knee. The Direct Ball Screw Drive Knee Prosthesis is currently being licensed by Ottobock, who will develop and manufacture the prosthesis to be sold worldwide. Read the open-access paper here.

K2 Knee

This active knee prosthesis module is designed for individuals with an above-knee amputation and lower mobility class. The K2 Knee Prosthesis is a lightweight knee prosthesis module, weighing approximately 1.65 kg. The main frame is aluminum to retain the lightweight quality of the knee prosthesis. A quasi-direct drive motor with a ball screw is utilized to reduce the noise of the device. The ball screw is attached to the PVT (passive variable transmission) unit to flex and extend the knee prosthesis. At the base of the knee prosthesis, a titanium ground reaction force sensor measures the force and torque readings necessary to control the knee prosthesis. The knee prosthesis can achieve a maximum torque of 60 Nm in both flexion and extension. The K2 Knee Prosthesis is designed to assist users in level-ground walking and with sit-to-stand movements.

Direct Ball Screw Drive Knee Exoskeleton

The Direct Ball Screw Drive Knee Exoskeleton uses similar actuation technology to our knee prostheses, combining direct ball screw drive with torque-sensitive actuation to overcome some key limitations of robotic actuators. By passively adapting the transmission ratio in response to changes in knee torque, the exoskeleton achieves higher torque density and torque-to-inertia ratio than current state-of-the-art exoskeleton actuators. The robotic actuator is fully enclosed and is used in conjunction with a clinical-grade carbon fiber Knee-Ankle-Foot Orthosis (KAFO). This is our 3rd generation knee exoskeleton.

Utah Ankle Exoskeleton

The ankle exoskeleton project aims to assist individuals with ankle weakness resulting from hemiparesis following a stroke. The Utah Ankle Exoskeleton is lightweight and fully integrated, with high torque density. Preliminary results suggest that ankle exoskeleton assistance can lead to more normative kinematics and increased foot clearance, reducing compensatory movements and fall risk. Read the paper here.

Utah Passive Ankle

The Utah Passive Ankle uses articulated ankle and toe joints attached to a carbon fiber frame and connected to each other with a compression spring to enable ambulation. The passive spring component is modular, allowing for different springs of different stiffnesses to be swapped for testing at different weights or activities. Since the device does not have a motor, it is much lighter than a powered device while maintaining the ability to provide assistive torque during gait.

Two-Degree-of-Freedom (2DOF) Hip Exoskeleton

The Two Degree-of-Freedom Hip Exoskeleton uses a novel parallel actuation mechanism that allows it to provide torque in the sagittal and frontal planes simultaneously, while maintaining a lightweight and compact form factor. The ability to provide up to 30 Nm in sagittal plane and 20 Nm in the frontal plane simultaneously opens up new research avenues in modulating balance for patient populations. See our design paper and preliminary study on modulating step width in healthy subjects here, and our conference paper here (pdf).

Composite Hip Exo (aka Hope)

The Composite Hip Exo uses a novel transmission system combining composite springs and non-linear kinematics to achieve high efficiency over wide ranges of torque and speed. The actuation and sensing are fully enclosed in a strong, lightweight carbon-fiber shell, which also acts as the frame of the exoskeleton. The carbon fiber shell is only 30mm wide and connects to the user through a soft, 3-d printed interface for comfort and adaptability. Check out videos of our preliminary tests on an able-bodied subject here, here and here. Check out the publication here.

Custom Electronics and Embedded Systems

We design our electronics in-house to address the unique challenges of wearable robotic devices: building complex, high-power systems within extreme space constraints. Custom electronics allow us to create smaller, lighter devices, tailor capabilities to our research needs, and achieve higher performance. Read more about our Custom Adaptive Boost Converter Module, our Custom Battery Management and Charging System, and our Custom Embedded Systems.

COMPLETED PROJECTS

Torque Adaptive Knee (aka Bonnie)

The Torque Adaptive Knee uses a novel transmission system that passively adapts to the load on the output joint, improving motor efficiency. This novel transmission system comprises an elastic element that strategically stores and releases energy during ambulation, leading to better performance and efficiency. These innovations enable the Torque Adaptive Knee to be lightweight, yet strong, and efficient. The Torque Adaptive Knee has been designed to satisfy ISO standards. We plan on sending it home with some of our subjects to understand the effects of a powered knee on mobility in real life. Check out a demonstration of the Torque Adaptive Knee here and the paper in Science Robotics here.

Bionic Ankle Foot (aka Clyde)

The Bionic Ankle Foot uses articulated toe and ankle joints powered by an innovative transmisson system located inside the lightweight and sturdy carbon fiber foot shell. During ambulation, mechanical energy is transferred from the toe to the ankle joint. Imitating the biological foot-ankle complex. This mechanical energy exchange mechanism increases the efficiency and effectiveness of propulsion. The Bionic Ankle Foot contains batteries and electronics. So, it can be used as a stand-alone device by individuals with below-knee amputations or in combination with a Torque sensitive Knee (aka Bonnie) for individuals with above-knee amputations. Check out a demonstration of the Bionic Ankle Foot here, and papers here and here.

The Bionic Ankle Foot uses articulated toe and ankle joints powered by an innovative transmisson system located inside the lightweight and sturdy carbon fiber foot shell. During ambulation, mechanical energy is transferred from the toe to the ankle joint. Imitating the biological foot-ankle complex. This mechanical energy exchange mechanism increases the efficiency and effectiveness of propulsion. The Bionic Ankle Foot contains batteries and electronics. So, it can be used as a stand-alone device by individuals with below-knee amputations or in combination with a Torque sensitive Knee (aka Bonnie) for individuals with above-knee amputations. Check out a demonstration of the Bionic Ankle Foot here, and papers here and here.

Ergo Knee Exo (aka Sasha)

The Ergo Knee Exo is a research knee exoskeleton designed to study ergonomics and human-robot interaction. Its design features one actuated joint, to assist/resist the knee flexion-extension, and four passive joints, to automatically and passively align the powered joint axis to the anatomical knee joint axis. Different from most powered exoskeletons, the Ergo Knee Exo has a symmetrical design: its mechanical structure wraps around the leg, rather than being positioned laterally, to avoid torsion on the wearer’s leg. The Ergo Knee Exo was designed by a team of undergraduate engineering students. Check out a video here.

Variable Transmission Knee (aka Juliet)

The Variable Transmission Knee uses a novel transmission system that adapts the motor torque and speed to the demand of different ambulation tasks. For example, the transmission ratio is high for tasks that require high torque and low speed, such as standing up from a seated position, and low for tasks that require high speed and low torque, such as swinging the leg forward in walking. This innovation enables the Variable Transmission Knee to be lighter, stronger, and more efficient than available powered knee prostheses. Check out the videos here and here. Read the article from PC magazine here and the scientific publication here.

Powered Polycentric Ankle (aka Romeo)

The powered polycentric ankle uses a novel polycentric design that combines structural and power transmission function in the same mechanism to achieve high-power capabilities and ultra-low weight. By producing up to 130 Nm of torque and weighing only 800g, the powered polycentric ankle matches the torque capability of the human ankle joint during ambulation while being much lighter. You can find more info and videos here and download the scientific publications here and here.

The powered polycentric ankle uses a novel polycentric design that combines structural and power transmission function in the same mechanism to achieve high-power capabilities and ultra-low weight. By producing up to 130 Nm of torque and weighing only 800g, the powered polycentric ankle matches the torque capability of the human ankle joint during ambulation while being much lighter. You can find more info and videos here and download the scientific publications here and here.

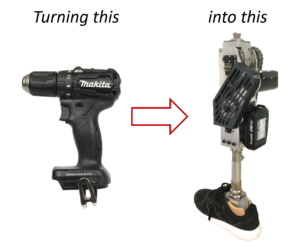

Open Leg Bionics

The goal of this project is to make powered prostheses more accessible. To accomplish this goal, we developed a powered knee prosthesis from readily available mechatronic components and using only simple machining tools. We believe that sharing the technical drawings and design instructions of our powered knee prosthesis will help anyone interested in the field to contribute to our long-term goal of making powered prostheses more accessible, to advance the research being done, and to promote STEM education. For this reason, we made our design open-source. Check out a video here.

Hybrid Knee

We developed a novel hybrid actuation system for robotic knee prosthesis that combines a conventional passive spring/damper system with an innovative variable transmission based on slider-crank design. The Hybrid Knee can work in passive mode, to achieve quiet standing and walking, and, in active mode, to helping subjects stand up from a seated position and ambulate on stairs. You can read more here and download the scientific publication here.

We developed a novel hybrid actuation system for robotic knee prosthesis that combines a conventional passive spring/damper system with an innovative variable transmission based on slider-crank design. The Hybrid Knee can work in passive mode, to achieve quiet standing and walking, and, in active mode, to helping subjects stand up from a seated position and ambulate on stairs. You can read more here and download the scientific publication here.

Adaptive Positioning Ankle

The Adaptive Positioning ankle uses a novel non-backdrivable actuation system based on a cam design resulting in an ultra-low profile--50mm built height--that would have been impossible to obtain with conventional transmission systems. Its control system adapts to the ground inclinations and actively increases foot clearance in swing phase, making ambulation safer and more comfortable for transtibial amputees. You can read more here and download the scientific publication here.

Robotic Retrofit Prosthesis

We designed a robotic system that can transform a conventional passive prosthesis into a powered robotic leg, thus allowing transfemoral amputees to perform activities that would not have been possible with their prescribed passive prostheses, such as climbing stairs. The Robotic Retrofit Prosthesis comprises two main functional elements: (1) a powertrain, which includes the motor and the primary transmission system, and (2) a motorized clutch that engages the motor and the primary transmission system during activities that require positive power such as standing up from a seated position or climbing stairs. Read More.